Discover Brampton commercial cleaning and sanitation experts who comply with CSA, WHMIS, and Peel Public Health. We provide SOPs, SDS access, detailed tracking, precise mixing records, and time-tracked evidence. We verify disinfection with ATP/fluorescence, guarantee dwell times, and employ ECOLOGO/Green Seal, DIN/EPA-registered chemistries. Staff functions off-peak with access controls, color-coded tools, and secure tracking for disinfectants. Verifiable documentation, CAPA workflows, and specialized protocols (office, retail, healthcare, industrial) are included. Discover how we limit interruptions while improving standards.

Key Takeaways

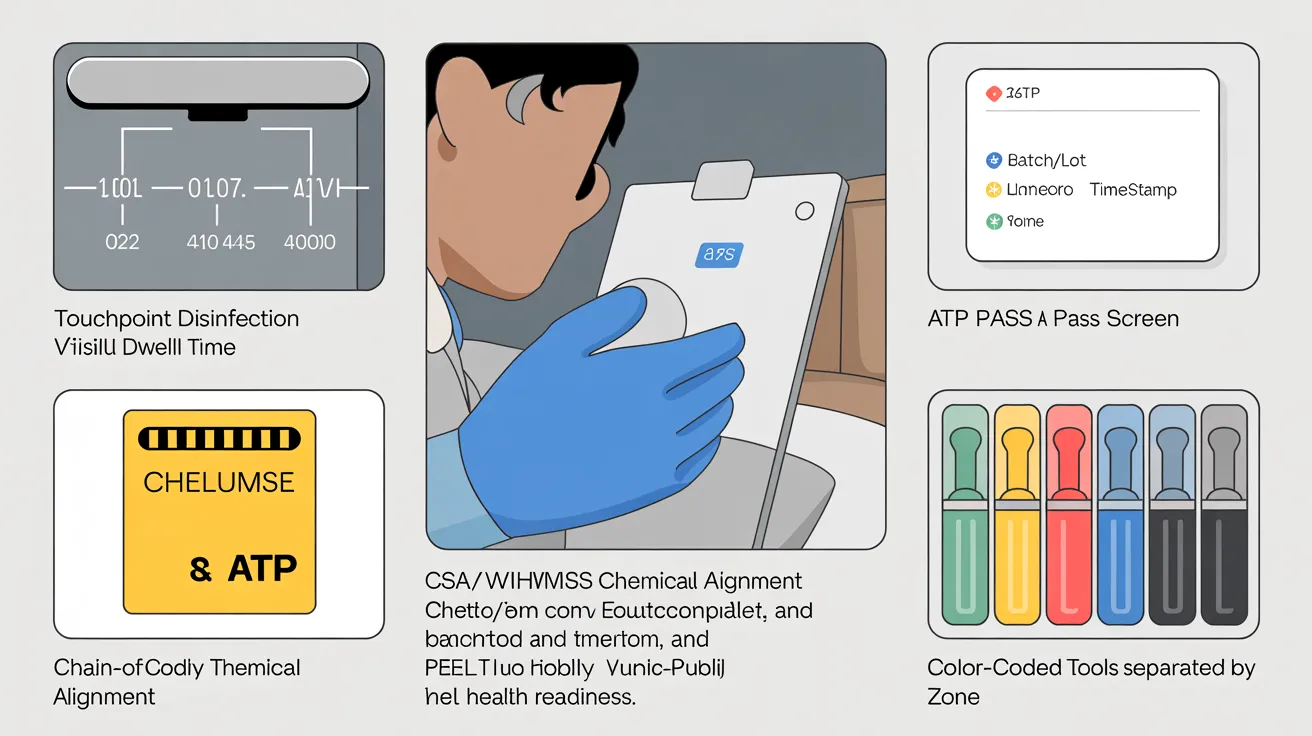

- Comprehensive SOPs following CSA, WHMIS, and Peel Public Health guidelines with documentation prepared for audits containing lot tracking, SDS libraries, and verified service timestamps.

- Risk-based cleaning approach: incorporating comprehensive touchpoint mapping, EPA-certified cleaning solutions, verified contact times, ATP and fluorescence validation, and regular third‑party microbiological analysis.

- Operational excellence: utilizing non-peak timing, small specialized teams, access control, secure tracking for chemicals, and calibrated dispensing with service records.

- Environmental stewardship: Green Seal/ECOLOGO certified solutions, automated dilution technology, advanced microfiber technology, comprehensive waste audits, and ISO 14001-aligned sustainability KPIs.

- Complete QA and quality control with supervisor audits, CAPA workflows, retraining protocols, and regulatory reports designed to meet municipal requirements, insurance standards, and regulatory bodies.

The Importance of Professional Cleaning for Brampton Businesses

Though daily maintenance keeps areas presentable, expert cleaning validates your Brampton facility meets safety, health, and compliance protocols. You need documented procedures matching local guidelines, approved chemistries, and accurately adjusted equipment to minimize risk exposure and contamination. Trained professionals employ standardized SOPs, designated tools by color, and precise dwell-time controls to guarantee complete sanitization and residue cleanup without damaging surfaces.

You can expect risk assessments that map foot traffic, contact areas, and ventilation effects, then establish measurable frequencies and QA checks. Seasonal considerations matter: cold weather necessitates doorway washing and matting upkeep; summer humidity requires dehumidification support and mold prevention; transitional seasons introduce airborne particles requiring advanced filtration and overhead maintenance. Thorough logs, SDS accessibility, and waste handling procedures streamline audits and prove compliance.

Business Segments: Offices, Retail, Healthcare, and Industrial

Your facility demands cleaning standards that match commercial space needs-touchpoint disinfection, scheduled floor upkeep, and refuse sorting-while following local health and safety bylaws. For healthcare, you need CSA- and IPAC-compliant procedures, EPA-approved sanitizing agents, validated dwell times, and tracking documentation for biohazard handling. In industrial settings, you require WHMIS/GHS labeling, equipment isolation protocols, HEPA and hazardous dust control, and audit-ready SOPs.

Workplace and Store Protocols

As operations extend over various facilities from offices to retail spaces, healthcare centers, and industrial locations, sanitation procedures need to comply with sector-specific regulations and verifiable quality controls. For office and retail environments, you must establish timing, methodology, and confirmation protocols per section. Utilize floor plans to chart traffic intensity, touchpoints, and material sensitivities, then set task lists by risk tier. Establish suitable cleaning solutions, concentration levels, and application times; document SDS access and dispenser calibration.

Establish employee protocols for: proper glove usage between areas, cable management, noise-reduction practices, and caution markers for slip prevention. Create a color-based organization for tools to eliminate contamination between areas in restrooms, break rooms, and public spaces. Schedule periodic HEPA filtration, microfiber system updates, and disposal segregation. Verify performance using biological monitoring, maintenance records, and remediation processes linked to quality thresholds and client service agreements.

Healthcare and Industrial Standards

Given that healthcare and industrial settings maintain increased risk profiles, we utilize validated procedures that meet regulations and withstand audit scrutiny. You receive site-specific operational protocols compliant with CSA, Public Health Ontario, and OSHA/WHMIS standards. We utilize color-coded tools, closed-loop chemical dilution, and barcode-logged tasks to secure accountability, infection control, and contamination mitigation.

Within our clinics, we implement Spaulding classifications, perform terminal cleaning, and employ EPA-registered disinfectants with documented wet contact times. We verify outcomes through bioluminescence monitoring and comprehensive audit checklists. Areas containing sharps undergo puncture-resistant waste disposal and detailed chain-of-custody monitoring.

Within industrial zones, we execute LOTO coordination, combustible dust control, and specialized non-sparking equipment usage. Floors undergo thorough degreasing with slip resistance verification. We maintain instrument accuracy, oversee SDS databases, deliver hazard communication training, and generate compliance documentation meeting your audit protocols and insurer requirements.

Essential Sanitization Guidelines for Frequently Contacted Surfaces

Although regular cleaning clears visible dirt, sophisticated disinfection protocols target microbial populations on high-touch surfaces with validated, measurable procedures. You'll begin with touchpoint assessment to inventory commonly touched surfaces including doors, railings, switches, taps, elevator buttons, payment systems, and shared equipment. Assign risk tiers, define dwell times per EPA-registered disinfectant, and note material compatibility to minimize surface degradation. Systematize sequence: preliminary cleaning, application, wet contact maintenance, and validation.

Utilize electrostatic application for comprehensive coating of complex surfaces; adjust nozzles, verify droplet size, and control pass speed. Perform ATP testing or fluorescence markers for immediate process verification, and schedule periodic external laboratory testing for outcome validation. Train staff on safety equipment protocols, product documentation review, and lot tracking. Log batch numbers, chronological data, and staff identifiers for quality verification and event tracking.

Eco-Friendly Products and Sustainable Practices

You'll select eco-friendly cleaning products that meet ECOLOGO or Green Seal standards and adhere to WHMIS and SDS guidelines. You'll establish waste management methods, incorporating microfiber solutions, dilution control, reusable dispenser options, and source-separated recycling following Brampton and Ontario click here guidelines. You'll verify performance with VOC thresholds, biodegradability requirements, and monthly audits to track compliance and ongoing improvement.

Green-Certified Cleaning Products

Implement a higher compliance standard by mandating green-certified cleaning products that comply with respected standards including ECOLOGO (UL 2792/2795), Green Seal (GS-37/GS-53), or EPA Safer Choice. In your green certification summary, document the product name, certification ID, dilution ratios, pH range, VOC content, and SDS references. Mandate third-party certifications on containers and confirm listings in each certification authority's online registry.

Choose cleaning products designed for microfiber, autoscrubbers, and touchpoint protocols. Choose cleaning agents with rapid biodegradation, non-NPE formations, and low-aquatic-toxicity ratings. Establish residue limits to support allergen minimization on heavily accessed zones and in indoor air quality-critical spaces. Standardize controlled dispensing systems to prevent overuse and preserve ppm accuracy. Instruct team members on contact duration for disinfectant alternatives meeting Safer Choice's partner criteria. Audit quarterly, analyze residual compounds, and track exceptions with improvement steps.

Methods to Reduce Waste

While adhering to strict hygiene standards, establish waste reduction by standardizing reusable, repairable, and refillable systems across sites. Start with Waste audits to analyze material streams by weight, contamination rate, and disposal cost per department. Apply results to specify robust dispensers, concentrated chemicals, microfiber equipment with controlled cleaning and color-marked receptacles. Enforce vendor take-back for packaging and pallet recovery.

Integrate compost programs for organic materials generated in food preparation areas, verifying that bin liners comply with ASTM D6400 and waste handlers accept them. Optimize collection timing based on bin fill-level data to eliminate overflow and pest concerns. Train personnel with operational guidelines, visual guides, and regular training sessions. Measure performance metrics: recycling effectiveness, per-capita disposal, and incident nonconformities. Record procedures to comply with municipal bylaws and ISO 14001 criteria.

Strategic Scheduling for Minimal Disruption

In line with business operations, customizable scheduling guarantees cleaning takes place outside busy periods to eliminate operational delays and income reduction. You specify specific service windows, backed with after-hours coordination, so teams operate when foot traffic and production are at their lowest. We analyze your operating calendar, blackout periods, and official holidays, then align task sequences to avoid conflicts with incoming goods, reviews, and repairs.

To minimize disruption, we implement phased workforce deployment with position-based guidelines, temporal monitoring, and service level benchmarks. Personnel strictly follow workspace comfort parameters, and work with rapid-cure solutions to decrease turnaround time. Security protocols, key tracking, and documentation systems maintain oversight. We meticulously record performance data, issue management, and safety reporting to fulfill operational guidelines, workplace regulations, and local ordinances while preserving efficiency.

Deep Cleaning vs. Routine Maintenance: Understanding the Basics

Because risk management and compliance protocols change by task, it's crucial to implement a clear distinction between routine maintenance (scheduled hygiene maintenance to maintain sanitation levels) and thorough sanitization (regular invasive remediation that restores difficult-to-access and high-risk areas). You should allocate regular cleaning to frequently contacted areas, restrooms, floors, and common tools using validated cleaning solutions, microfiber tools, and time-specific sanitizers. You'll log schedules, safety gear, procedures, and inspection findings.

Schedule thorough sanitization as periodic maintenance according to hazard mapping: key zones such as ceilings, ventilation returns, grout areas, equipment backs, drains, and permeable materials. Utilize ATP or fluorescent markers to confirm pre/post results, upgrade to HEPA systems, descalers, and steam treatment where biofilm risk exists. Standardize operational procedures, color identification, and tool isolation to minimize cross-contamination. Document results, improvement steps, and inspection timing to ensure compliance.

Meeting Health and Safety Requirements

Your maintenance plan will only be effective if it complies with statutory and industry requirements, so connect every task to specific standards and maintain proof of conformity. Map each surface, chemical, and method to industry standards and regulatory requirements. Update SDS libraries, dilution logs, lot tracking, and measurement verification logs. Train staff on proper safety equipment use and emergency procedures. Implement color-coded tools and closed-loop chemical systems to avoid cross-contamination. Schedule internal audits, keep checklists, photos, and corrective actions to drive inspection readiness. Monitor regulatory updates from Peel Public Health and provincial authorities; update SOPs, signage, and risk assessments accordingly. Verify disinfectant contact times with ATP testing and log results. Manage access to storage, label secondary containers, and maintain ventilation checks with documented maintenance.

Custom Solutions for Event Aftermath and Peak Traffic Periods

Despite compressed maintenance timeframes during peak periods, you require fast, regulation-adherent sanitization that ensures cleanliness levels without operational disruption. Our team implements targeted high-traffic cleaning procedures that strategically segment spaces, evaluate soil conditions, and deploy rapid-cure solutions validated by ASTM and Health Canada standards. Our team conducts complete sterilization of common contact points including rails, seats, and concessions applying DIN-registered products with documented contact times.

In floor maintenance, we utilize non-slip detergents, machine clean paths, and microfiber recovery to minimize re-soiling. Waste management is conducted per municipal bylaw, with sharps, glass, and organics handled via marked receptacles and tracking. After-event odor management utilizes direct elimination, enzyme-based solutions, and MERV 13-18 air filtration to restore IAQ benchmarks. Washroom servicing include scale elimination, grout disinfection, and restocking according to occupancy projections.

Skilled Professionals and Quality Management Systems

These operational procedures only function when certified professionals carry out them under a documented QA framework. You rely on trained technicians who adhere to SOPs aligned with CSA, WHMIS, and manufacturer guidelines. Each specialist undergoes primary and recurring skill evaluation on chemical interaction, dwell times, microfiber sequencing, and ATP verification. You require chain-of-custody documentation for disinfectants, calibrated meters, and color-designated area controls to prevent cross-contamination.

The quality assurance process operates in a closed-loop system. Management performs systematic evaluations against standardized criteria, sampling high-touch surfaces using ATP thresholds and visual standards. Compliance gaps generate remedial responses, root-cause analysis, and targeted retraining. Proof of service delivery receives temporal validation, with photo documentation stored in compliance records for pattern evaluation and assessment. Three-month emergency exercises, PPE fit testing, and competency update sessions keep skills fresh and objectively assessed.

Finding the Ideal Cleaning Company in Brampton

In evaluating a Brampton cleaning partner, look beyond pricing and review verifiable compliance, employee protocols, and quality controls. Validate WSIB coverage and insurance coverage limits, along with professional accreditations (like ISSA, GBAC). Ask for operational protocols, chemical inventories with SDS, and equipment service documentation. Confirm criminal background screenings, vaccine protocols where applicable, and appropriate supervision levels. Ensure certified education on WHMIS, bloodborne pathogen protocols, and local regulations, encompassing waste handling and sharps handling procedures.

Assess quality control frameworks including scheduled audits, contamination detection methods, and CAPA workflows with timestamped remediation steps. Request key indicator tracking (response times, error frequencies) and problem resolution procedures. Align requirements with cost parameters through defined intervals, work schedules, and operational standards. Verify eco-friendly documentation and ventilation compatibility. Establish contingency plans for outbreaks, supply disruptions, and after-hours access control.

Popular Questions Answered

Contract Durations and Cancellation Guidelines for Cleaning Services

Most cleaning service contracts commonly operate on month-to-month, 6-month, or 12-month terms. Contract documentation outlines information regarding scope, KPIs, renewal options, and pricing adjustments. Cancellation terms typically require one to two months' notice for standard cancellation, while immediate termination is allowed for critical problems including safety violations, insurance lapses, or performance failures. Early termination typically involves financial penalties. Make sure communication requirements (mail or email), resolution timeframes (up to two weeks), and financial settlement terms are clearly defined to maintain compliance.

Are Emergency Spill and Biohazard Services Available After Hours?

Indeed - we deliver emergency services for spills and biohazards. Just like an emergency signal breaking through darkness, you can expect a fast emergency crew within 60-90 minutes. Technicians arrive in protective equipment, set up biohazard containment, isolate HVAC if required, and follow OSHA, WHMIS, and local public health protocols. We document chain-of-custody for waste, conduct ATP verification, and deliver incident reports. Just give phone authorization; we respond right away and bill under emergency service rates.

How Are Staff Vetted, Background-Checked, and Insured for On-Site Work?

We provide rigorously vetted via a multi-stage screening procedure. We conduct comprehensive national and local criminal background checks, validate identity, and confirm right-to-work status. We require two professional references while we verify employment history and performance. Drug testing is conducted as mandated by client SOPs. Everyone must finish required safety certification, WHMIS/OSHA training, bloodborne pathogens training, and site-specific orientation. We ensure annual background re-checks for all personnel. All technicians maintain general liability, pollution, and workers' compensation insurance; insurance certificates and endorsements will be provided upon request.

Can Services Connect With Building Security and Access Management Systems?

Indeed. You can align operations with your building's access management and security measures through established integration procedures and rigorous credential management. You'll provision duration-specific credentials, permission-based roles, and geographic access limits. We'll enable system integrations via API or OSDP, audit-log syncing, and guest access procedures. You'll implement multi-factor authentication, minimal access rights standards, and verified credential assignment. We'll establish standard operating procedures, incident response, and immediately deactivate permissions upon scope changes. You'll get compliance documentation and access exception alerts.

What Reporting Tools and Dashboards Monitor Cleaning Tasks and Service Quality?

A comprehensive KPIs dashboard and mobile logging system delivers detailed, dependable compliance oversight. You'll have access to real-time updates, including geotagged entries, time records and adherence to service agreements. You can sort data by zone, shift, or technician and create thorough documentation. The platform enables verification of supply consumption and conformity checking. Information security is maintained via role-based access controls and advanced data protection, while system interfaces allow thorough operational insights.

Final Thoughts

You're not just hiring cleaners-you're investing in a precision tune-up for your building's wellness. With calibrated disinfection for high-touch zones, green-certified products, and inspection-ready records, you'll meet standards like a metronome. Adaptable timing keeps operations humming, while special event recovery solutions eliminate event remnants. Skilled professionals, checklists, and QA inspections lock in consistency. Choose a Brampton service that demonstrates adherence, confirms outcomes, and grows alongside you-so your space shines like a well-instrumented lab, sanitized, secure, and compliant.